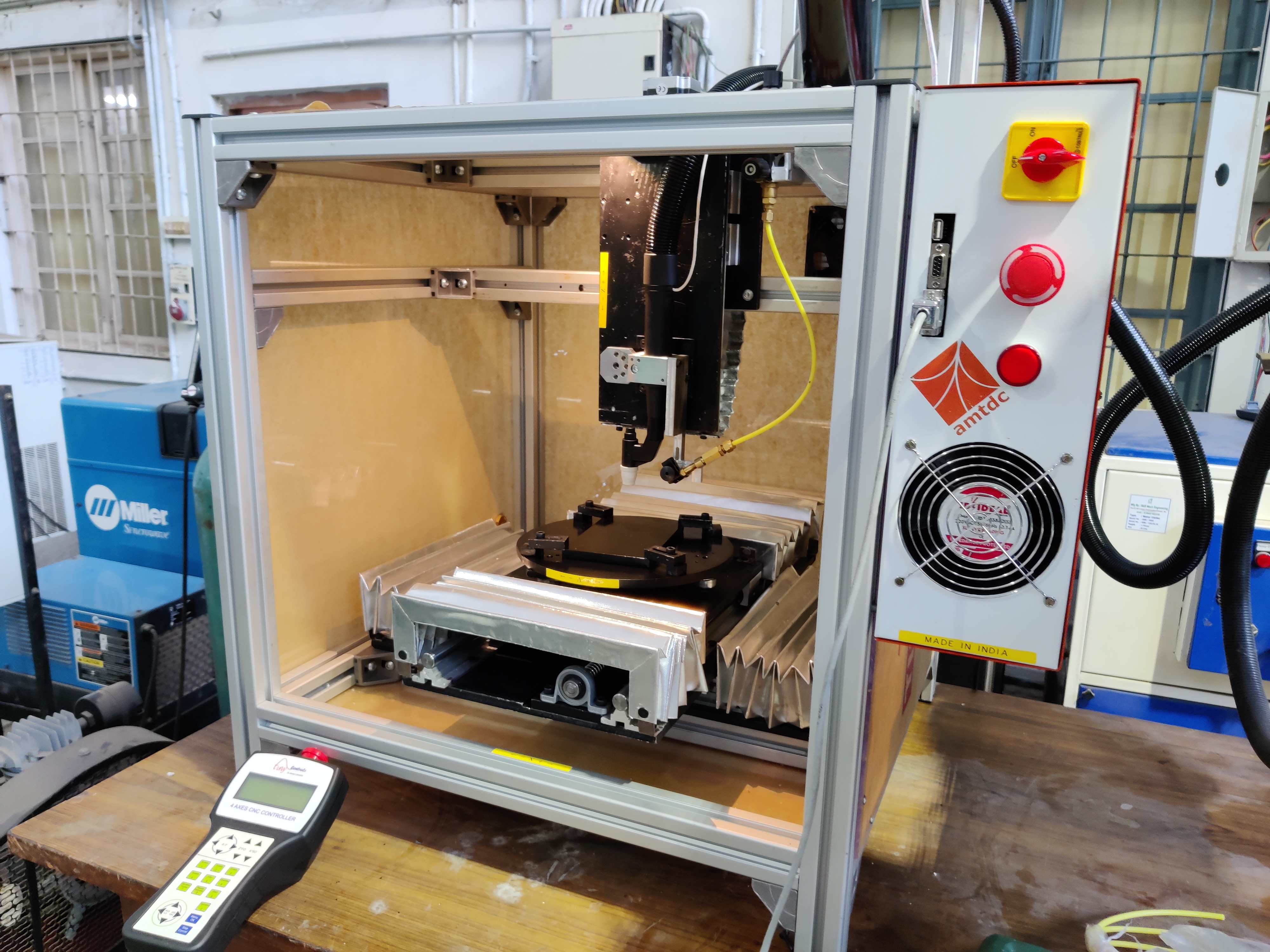

The entire machine is divided into four main working units:

a. X-axis slide movement

b. Y-axis slide movement

c. Z-axis slide movement.

d. A-axis rotary movement

This includes the controller system , programming features , alarms and troubleshooting , maintenance and service and wire feeder controlling for any material.

X-axis slide movement:

X-axis slide movement holds the base plate which carries the rotary table. The total movement of the X-axis slide is controlled upto 220 mm.

From the center point the X-axis slide moves left towards 110 mm and similarly towards right 110 mm from the center point.

Y-axis slide movement:

Y-axis slide movement is the base of the plasma deposition machine which carries the movement of X-axis. The total movement of the Y-axis slide is controlled upto 220 mm.

From the center point the Y-axis slide moves left towards 110 mm and similarly towards right 110 mm from the center point.

Z-axis slide movement:

Z-axis slide movement is vertical oriented and the base plate of Z-axis slide movement holds the plasma torch. The total movement of the Z-axis slide is controlled upto 150 mm.

A-axis rotary movement:

A-axis rotary movement is the rotary table movement. The total rotation of the rotary table is controlled up to 360 degrees.

Wire feeder:

Wire feeder has the capability of handling the wire diameter ranges from 0.6 to 1.4 mm and the wire feeder feed rate ranges from 50 to 2500 mm per minute.